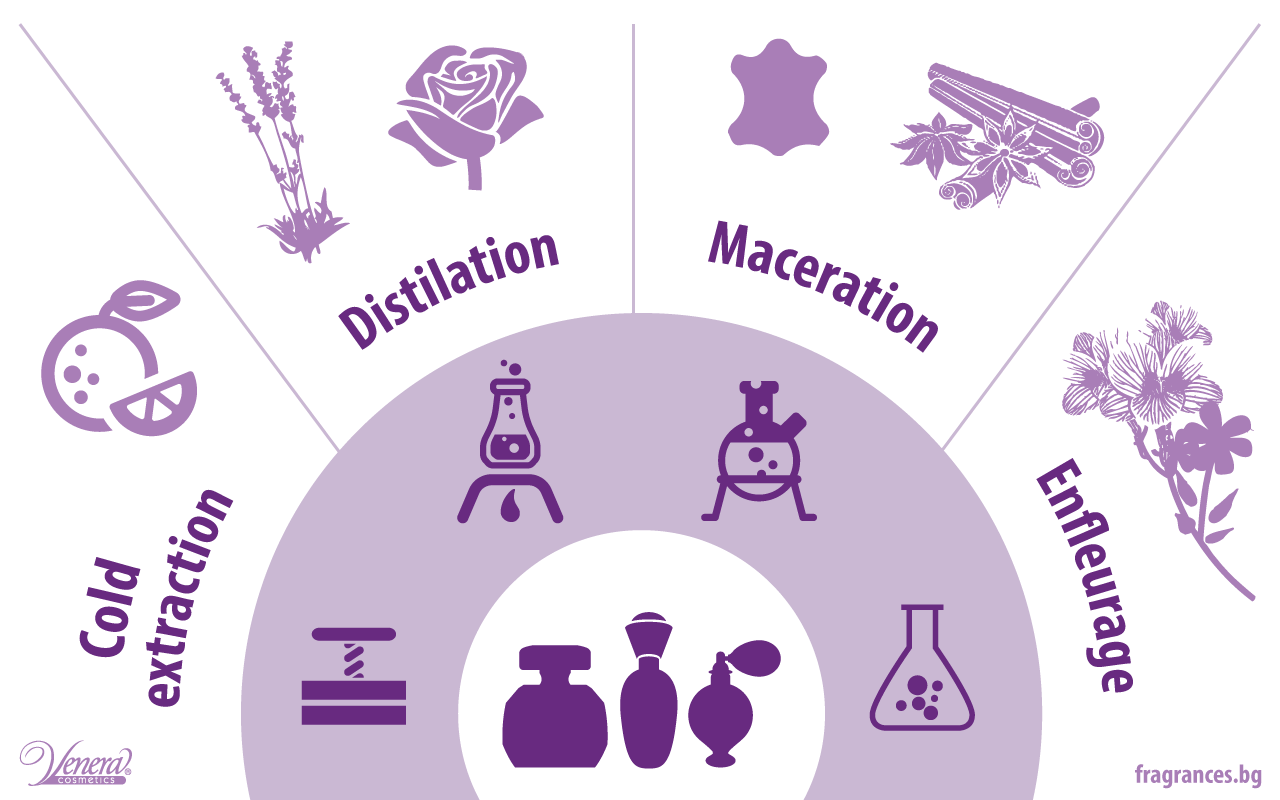

Perfume manufacturing techniques

It turns out that there are a lot of efforts to be made in order to create a perfume. Except for the complicated and delicate task of the perfumer to create the perfect perfume composition, the important role of the designer in the creation of a bottle and an appropriate design that would fit the composition, as well as the creative task to find the most appropriate name for the perfume, the task to extract the fragrance from the notes that are listed in the description is not at all easy.

Here are some of the most widely used perfume manufacturing techniques. Some of them have been known since Antiquity, while others are an accomplishment of the contemporary science:

Cold extraction

Yes, except for olives that we all know about this technique is used for the extraction of perfume notes as well. It is used mainly with citrusy notes (orange, lemon, grapefruit, mandarin, lime, etc) as their fresh and light scent wouldn’t survive any treatment that involves heat. It includes making numerous holes on the surface of the citruses’ peels and then mechanically pressing them to extract the fragrance oil.

Distillation

Probably the most often used technique when it comes to the production of spirits, distillation is also a widely used method for the extraction of the precious scent from different plants, fruit blossoms, and, of course, roses. There are different types of distillation:

- steam distillation – in this process the ingredients are heated in a water solvent and the steam that goes through them extracts the essential oils. It is used for the scent extraction of flowers, leaves, and stems.

- dry distillation – the process is the same, but the plant is heated directly (without the use of water). It is appropriate for the extraction of amber and different wood notes, adding to them the specific “burnt” effect.

- fractionation – this is a method in which different components of the raw material may be selected through distillation. Thus the perfumer can control the process, to a certain extent, selecting the characteristics of the result. Despite its higher price, this method is widely used among perfumers, because unpleasant (or undesired) notes can me eliminated with its help, creating a unique perfume note.

Maceration

Maceration is among the most often used methods for scents extraction for the perfumery’s purposes. It is used for the extraction of perfume ingredients from many plants as well as all notes from animal origin. It is a technique in which the raw material is diluted in a solvent that extracts the scented components. Today different solvents are used (like ethanol, for instance). The solvent extracts the scent from the plant and then it’s evaporated through heating. After that the perfume note is separated with the help of alcohol.

Enfleurage

Enfleurage is among the oldest techniques for perfume production. It is a process that involves animal (saturated) fat. The method is used for the extraction of fragrance from delicate raw materials like orange blossoms, jasmine, and tuberose. Despite the fact that it is extremely sparing for the raw material, it is rarely used today as it is not economically effective when it comes to the time needed for is successful execution and the quality of the final product.